| What is the effect of the slider? |

|

A slider is a part that can be expected to reduce damage to the engine and vehicle body when standing up or falling. Resin is often used as the cushioning material, and it is characterized by being softer and more self-lubricating than metal. In the event of a fall, the ground surface is scraped and the vehicle slides to reduce damage to the vehicle body, which reduces damage to the engine, which is the core of the motorcycle, and reduces the possibility of self-propelling, which is useful in terms of security. It is a custom part.

|

|

| Risk of wearing a slider. |

Speaking of sliders, frame-mounted cone-type frame sliders are common.

Many cone-type sliders use engine mount bolts, and if the impact cannot be completely eliminated when the slider falls, damage to the engine or frame may remain.

Also, if the cushioning part is completely scraped off, the head of the engine mount bolt may be damaged, making it difficult to remove the bolt.

In that case, what is required of the slider tends to be "to mitigate the damage more", but in reality, when driving such as winding and city riding, it also has the aspect of "dangerous if it slips too much", so I want to mitigate the damage. , The contradictory properties of not slipping too much must coexist.

|

|

| Behind the development of the engine cover slider. |

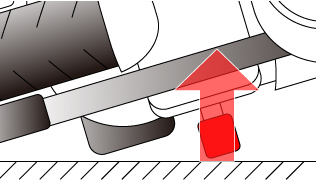

From the idea of being able to cushion the impact at a position below the frame slider and the engine cover for racing, which is also adopted in the MFJ regulation, the product that equips the engine cover with the slider function that is in high demand on the street Started development.

Damage to the engine (cover) increases the likelihood of inability to drive due to oil leaks. Also, if oil spills on the road surface, it will pose a danger to the following vehicle.

The basic design concept is the same as the frame slider, and it is a product with high cushioning power, suppression of overslip, and design. With a hybrid structure of aluminum block and POM resin, it is a high-class finish that has a machined texture while being a resin product. ..

"Motorcycle parts should be cool."

The developer's strong feelings are put into the unique modeling that suits each car model and the line of the machine path that is intentionally left.

|

|

|

| CBR1000RR |

ZRX1200DAEG |

|

|

| ZX-10R |

KATANA |

|

|

|

|

| The effect is doubled when combined with the frame slider. |

The frame slider and engine cover slider each have a fixed impact tolerance that can be protected individually, and it is difficult to increase that tolerance. Because there is a risk of getting caught during gliding, lengthening or increasing the cushioning material is not a solution. Therefore, Active recommends using the engine cover slider and frame slider together. By changing the number of grounding points from one to two, the force applied to the vehicle body can be dispersed and damage can be reduced.

|

| Example of the engine and slider touching down |

|

|

| When only the frame slider is attached |

When both are installed |

| Damage is concentrated on the frame slider |

Damage is distributed to the engine slider and frame slider |

|

| |

|

|

|

|