|

| Please tell me the flow to commercialization |

|

①Measurement of normal position

Finely measure the position of the normal step and peripheral parts. |

②Determining FCK position

The most important item that determines the character of the product. For example, a racing machine that always banks is taken in the position raised by lowering it "significantly" backward due to its riding posture and vehicle behavior.

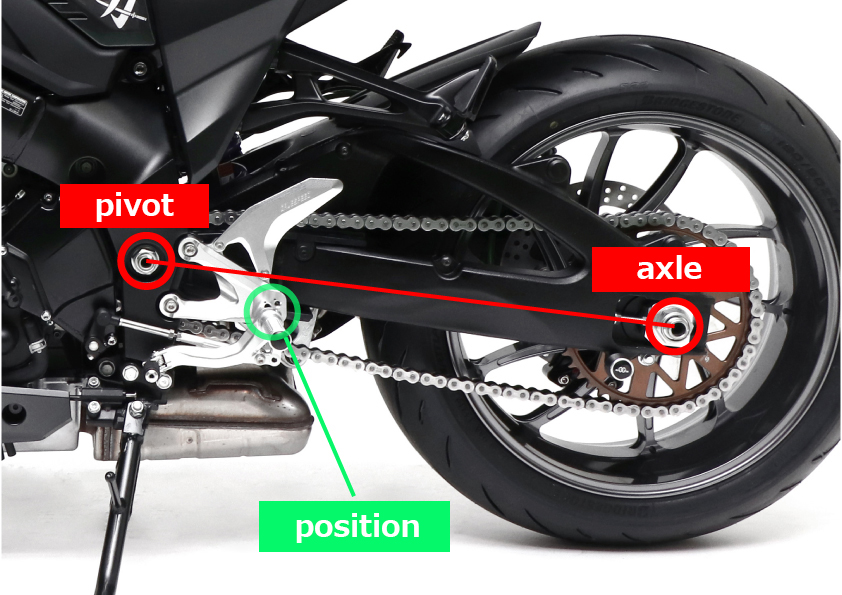

However, FCK is required to be able to operate comfortably even on the street, so it will be impossible to do it in the same posture as the racer. Therefore, one policy is to aim for a position that "does not go above the line connecting the pivot and rear axle (photo)" and "does not lower too far behind" (race vehicles are above this line). ). Of course, not only the calculation but also the behavior of the rider while driving such as acceleration / deceleration and cornering are taken into consideration when adjusting. |

|

|

③Arrangement and design of necessary parts

Determine the placement of the peripheral parts while confirming that there is no problem in operation without touching the surrounding parts regardless of the position of the step bar. The position of the rear master cylinder is also taken into consideration so that the genuine brake hose can be used as it is.

|

④Design

Design based on the arrangement of ③. "Simple" in the concept of FCK is a functional beauty that is born after pursuing performance and rigidity. By using only one main plate, your legs will not stick out too much and you will be in a good position without disturbing the operation. As an aside, the motoGP machine also uses a simple single plate.

|

⑤Prototype / installation / test

Make a resin prototype with a 3D printer and attach it to the vehicle. Even if it takes a long time to reach ④, it often happens that when you actually put it on, it doesn't go as you expected. In that case, review the design again and repeat until you are satisfied.

If you can make a resin that has no physical or external problems, manufacture it with the same aluminum material as the mass-produced product and go to the running test. The final judge will be made by carefully evaluating the results of installation, test drive, and disassembly.

|

|

|

⑥Commercialization

Once the specifications are finally decided, it will be mass-produced. From here, the baton touch from the development department to the product management section.

The Product Management Department inspects, sets up (assembles), packs and ships parts. The number of parts is very large and there are many moving parts, so delicate technology is required, but the production staff is doing very high quality work. If you have any doubts or concerns, don't neglect to check and be sensitive to minor differences. I think it is the result of the efforts of the production staff that we can provide good products to our customers.

|

|

| What is your commitment to KATANA's FCK, which Active chose as the 2020 show model? |

|

The show model KATANA is equipped with a large number of GALE SPEED products, but I think that FCK has an eye-catching coolness among them. For example, the shape of the heel plate is based on the motif of "the tip of a Japanese sword", but this is where I was particular about, and in fact it was sharper at the time of design, and I even added a blade pattern. When I made a prototype, the hem of my pants got caught and it didn't work (laughs). By repeating such trials and errors, it finally became the current form. I am conscious of harmonizing with the silhouette of the entire vehicle so that only the FCK does not stand out. Not only for KATANA, but for all car models, we are particular about "fitting well and positioning it inside the car body as much as possible (= not too wide)", so please pay attention to it! |

|

| Finally, please have an appeal of FCK! |

|

As a designer, I would like you to first experience the basic concepts of "good operability," "simple," and "high rigidity." The feel of the moment you put your foot on it. The difference in the feeling of operating the pedal. Easy to ride and handle. And please feel "coolness". We are very particular about the parts other than the functions, so there is no doubt that it will be a "fun to ride" and "happy to see" bike.

|

|

|

| Production Edition Product Management Section Mr. O |

| Please tell me the manufacturing process of Elaborate Foot Control Kit (FCK). |

|

①Inspection of parts

When FCK components arrive, we "inspect all parts 100%". The number of parts in one kit is 70 or more, and even a slight dimensional difference may result in a large error in the end if it is overlooked. For this reason, we pay particular attention to clearance and the astringency of movement of moving parts, and in particular, we inspect sliding parts such as bearings that are related to operability in units of 1/100 mm.

|

②Manufacture for each block

| FCK does not assemble the whole at once, but divides it into blocks such as "heel plate assembly" and "change pedal assembly", and finally matches them. This is not only a manufacturing method, but also leads to a sales method that can quickly respond when the user wants to partially replace parts due to a fall or the like. |

|

|

③Overall assembly / confirmation

Once the parts for each part are completed, it is the final assembly. When putting the finished product in the box, we pay attention to the angle of the pedals, and we are conscious of it until the end so that the customer will be pleased when opening the box.

|

|

| How do you feel about the product called FCK as a person in charge of production? |

|

This product is differentiated from other companies' products as the GALE SPEED brand, and I feel that it is a very interesting product. Certainly it is very nerve-wracking as a person to make, and it is actually difficult. There are many orders from the development staff (laughs). But it's worth it and it's a very rewarding product. |

|

| What does it mean to use nerves, for example? |

|

| Anyway, the number of parts is large, and it is different for each model. There are many differences in tightening torque and angle, so you should always check the drawing and work. Although there are necessary items in the drawing, I add my own notes by drawing auxiliary lines and writing. Furthermore, in the future, we are making preparations to ensure that the person in charge other than ourselves can finish with the same quality. I think we must continue our efforts to make people say, "There is no mistake in active products." |

|

|

|

| Even in the company, Mr. O is said to "do detailed work for this person!" Finally, please have an appeal of FCK. |

|

I think this product is more active than ever in terms of quality and performance. I also always use my nerves to deliver products that are correct. We hope that you will experience the "high quality and functional" foot control kit that Active delivers. |

|

|

|

|